PVC self adhesive film has become one of the most efficient and cost-effective solutions for renovating walls, windows, cabinets, and furniture. Compared with traditional remodeling methods, pvc self adhesive film allows users to transform spaces quickly, cleanly, and with minimal budget. However, for many DIY users, the biggest concern during installation is one common problem: air bubbles.

Bubbles not only affect the visual finish, but also reduce adhesion performance and long-term durability. The good news is that, with proper preparation, the right tools, and correct installation techniques, pvc self adhesive film can achieve a smooth, professional, bubble-free surface every time.

This article provides a complete step-by-step guide based on real installation practices, helping DIY users and professionals understand how to apply pvc self adhesive film correctly, avoid common mistakes, and achieve long-lasting decorative results.

Understanding the Essential Tools Before Installing PVC Self Adhesive Film

Successful installation of pvc self adhesive film begins with the right tools. Each stage—from surface preparation to final trimming—requires specific equipment to ensure adhesion strength and surface smoothness.

Below is a detailed overview of commonly used tools and their functions during pvc self adhesive film installation.

Installation Tool Overview

| Category | Tool Name | Function |

|---|---|---|

| Surface Preparation Tools | Brush | Cleaning surfaces and applying primer (small areas) |

| Sandpaper | Smoothing uneven substrates | |

| Putty Knife | Applying filler and leveling compounds | |

| Roller | Applying primer evenly | |

| Grinding Machine | Sanding large surface areas | |

| Screwdriver | Removing screws, handles, and fittings | |

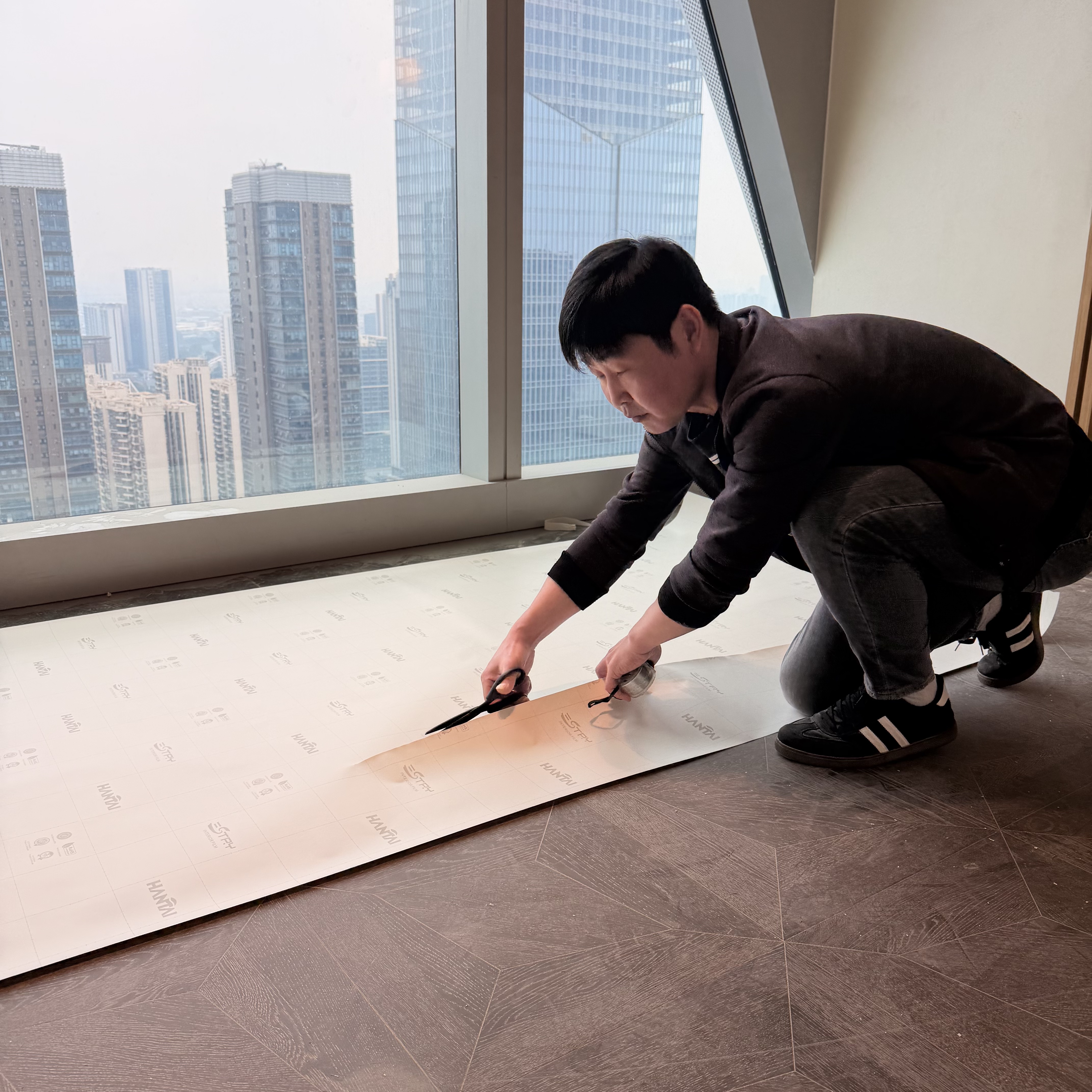

| Cutting & Measuring Tools | Scissors | Cutting pvc self adhesive film |

| Measuring Tape | Measuring surface dimensions | |

| Utility Knife | Edge trimming and corner cutting | |

| Masking Tape | Marking positions and alignment | |

| Marker | Dimension marking | |

| Application Tools | Wool Squeegee | Pressing film over large areas |

| Triangle Squeegee | Pressing corners and edges | |

| Edge Finishing Squeegee | Final edge smoothing | |

| Heat Gun / Hair Dryer | Heating film to improve flexibility | |

| Nylon Gloves | Hand protection | |

| Lighter | Corner sealing | |

| Auxiliary Materials | Putty | Filling small holes and surface defects |

| Joint Compound | Repairing cracks | |

| White Glue | Improving filler adhesion | |

| Primer | Strengthening surface bonding | |

| Towel | Cleaning and wiping |

Each tool plays an important role in achieving a flawless pvc self adhesive film installation, especially when working on large surfaces or irregular shapes.

Proper Surface Preparation: The Foundation of Bubble-Free PVC Self Adhesive Film

One of the most common causes of bubbling is poor surface preparation. Dust, oil, moisture, and uneven textures prevent pvc self adhesive film from bonding evenly to the substrate.

Before installation, surfaces must be clean, dry, smooth, and structurally stable.

General Surface Cleaning Steps

Clean the surface using mild soap and water to remove dust, grease, and residues

Ensure the surface is completely dry before application

Sand uneven areas with fine-grit sandpaper to achieve a smooth finish

Proper preparation significantly reduces trapped air during pvc self adhesive film application.

Surface Treatment for High-Absorption Substrates

High-absorption surfaces include gypsum board, cement board, concrete walls, fire-resistant boards, plywood, and other wood-based panels.

Recommended Treatment Process

Fill nail holes, seams, and surface defects using oil-based filler

Apply filler 2–3 times for deep cracks or severe damage due to shrinkage during drying

After complete drying, sand with 180- or 240-grit sandpaper

Ensure the surface is flat, smooth, and crack-free

Apply a dedicated primer before installing pvc self adhesive film

Important Note:

Oil-based filler is recommended for wood-based materials because it dries faster, has higher hardness, and bonds better with wood. Using standard putty or joint compound may cause cracking later, which can deform the pvc self adhesive film surface after installation.

Surface Treatment for Low-Absorption Substrates

Low-absorption substrates include marble, ceramic tiles, metal panels, and glass surfaces.

Recommended Treatment Process

Remove oil stains and surface contaminants completely

Apply tile-specific leveling compound 2–3 times

After drying, sand lightly with 280-grit sandpaper

Remove all dust and apply primer evenly

These steps improve adhesion and reduce the risk of pvc self adhesive film peeling or bubbling.

Step-by-Step Installation Process for PVC Self Adhesive Film

Apply Slowly and Evenly

Do not remove the entire backing paper at once

Peel the release liner gradually while pressing the film onto the surface

Use a squeegee to smooth the film in sections

Always work from the center outward, pushing air toward the edges to prevent bubbles.

Using Heat to Improve Adhesion and Flexibility

Applying gentle heat with a hair dryer or heat gun (low setting) softens pvc self adhesive film, allowing it to conform better to corners, curves, and edges.

Heating also activates the adhesive, making it easier to eliminate trapped air and ensuring a tighter bond.

Removing Small Bubbles Immediately

Use a squeegee to push small bubbles toward the edges

If bubbles persist, puncture gently with a fine needle and press out the air

Prompt correction prevents long-term adhesion issues.

Practical Installation Tips and Techniques

Measurement: Cut film at least 3 cm larger than the substrate

Doors: Apply the back side first, then the front

Cabinets: Install vertical surfaces first, then horizontal

Walls: Apply from top to bottom

Grilles: Apply 20–30 cm sections at a time; overlap seams at inner corners

Irregular Shapes: Start with simple areas, then complex shapes; use heat for deep contours

Ideal Temperature: 10–38°C for pvc self adhesive film installation

These techniques help achieve a cleaner finish and reduce installation errors.

Final Thoughts: Achieving Professional Results with PVC Self Adhesive Film

Installing pvc self adhesive film is not difficult when done correctly. With proper surface preparation, careful application, and the right tools, DIY users and professionals alike can achieve smooth, bubble-free results suitable for furniture renovation, wall decoration, and window enhancement.

PVC self adhesive film offers flexibility, durability, and visual impact—all without the cost and disruption of traditional renovation methods.

If you are looking for high-quality pvc self adhesive film that is easy to install and designed for long-term performance, feel free to contact us for professional guidance and product support.