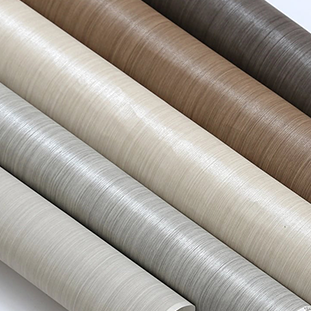

In the modern furniture manufacturing and interior decoration industries, more and more companies rely on pvc decorative film to achieve realistic wood grain, stone grain, metallic textures, and various design effects. However, among many pvc decorative film products that appear similar, why can some firmly bond to wooden substrates after being applied with flat lamination machines, vacuum forming machines, or wrapping machines—remaining stable for years without peeling—while others easily develop bubbling, warping, delamination, or detachment?

What key technology determines whether a seemingly thin piece of decorative film can truly bond to the substrate?

The answer often lies in a frequently overlooked yet critically important technical detail—the “back coating.”

Many purchasers, furniture factories, door manufacturers, and decoration material distributors focus more on patterns, scratch resistance, and thickness when choosing pvc decorative film, but they often overlook the quality of the back coating. In fact, back coating performance directly determines whether the film can truly adhere to wood substrates and determines its service life. As the industry transitions into colder months and ambient temperatures drop, more customers worry about adhesion issues caused by the weather. Therefore, “whether the back coating meets standards” has become one of the core criteria in evaluating pvc decorative film quality.

To help customers fully understand the importance of back coating, we will explain what back coating is, why it must be applied, how to test its adhesion performance, the scientific relationship between back coating and substrate bonding, and why HanTai’s laboratory tests prove our 60-dyne-level back coating quality. This article aims to help every consumer choose truly high-quality and reliable wood grain self adhesive film and building-grade PVC decorative films.

What Is the Back Coating of PVC Decorative Film and Why Does It Have Such a Huge Impact on Adhesion?

When you see a wood grain self adhesive film, marble effect pvc decorative film, or high-gloss pvc film, what you see is only the surface. The true reason it can firmly adhere to the substrate and maintain long-term stability is the invisible protective layer on the back—the back coating.

The back coating is a uniform polymer material applied to the backside of pvc decorative film. It functions like an “adhesion booster,” enhancing attachment strength in various applications.

Its functions include:

·Improving bonding with glues, hot-melt adhesives, PUR, white glue, etc.

·Preventing delamination in low-temperature environments

·Preventing rebound or bubbling after wrapping

·Enhancing stability during high-speed machine processing (flat lamination, vacuum ·forming, wrapping)

·Improving compatibility with various substrates (such as MDF, particle board, PVC board)

Without back coating, even the best glue and the best machines may still result in poor adhesion.

In the entire PVC decorative film industry, back coating is often more important than the surface texture itself.

Why Has the Dyne Value Become the Standard for Evaluating Back Coating Adhesion?

Many purchasers do not realize that the quality of back coating is not judged by feeling, but by surface tension (Dyne level).

According to National Standard GB/T 4216-2008 – Surface Tension Testing Method, a qualified pvc decorative film back coating must reach:

≥ 38 dyne

The higher the dyne value, the easier the back coating can “wet” and “penetrate” the glue, thus achieving stronger adhesion.

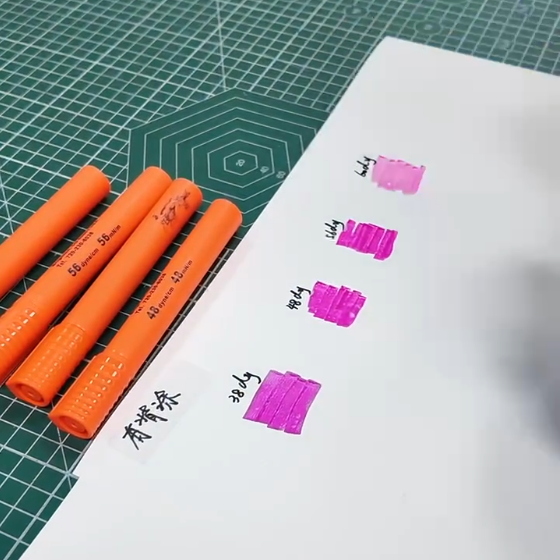

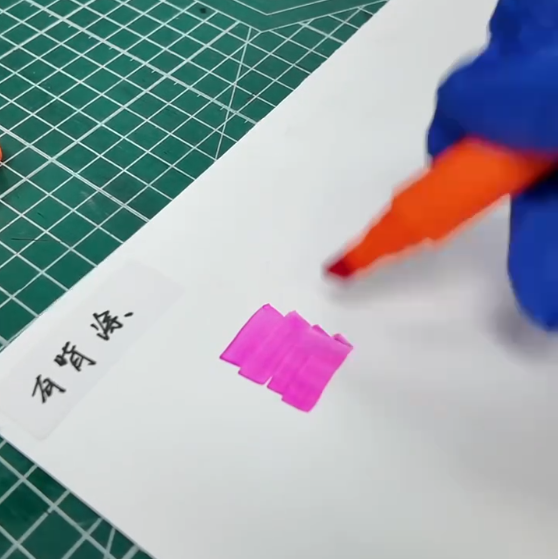

How Is Dyne Testing Conducted? Why Does HanTai’s Back Coating Exceed Industry Standards?

The testing method is very straightforward.

Prepare two samples of pvc decorative film:

·One with back coating

·One without back coating

Use a 38-dyne pen on both samples:

·If the line does not shrink → it meets the standard

·If it quickly beads or shrinks → it fails

However, in HanTai’s laboratory, we not only test with 38 dyne, but also with:

·48 dyne

·56 dyne

·60 dyne

We record the stability and shrinkage.

Final result:

HanTai’s PVC decorative film shows no visible shrinkage even at 60 dyne.

This means:

✔ Extremely stable back coating

✔ Adhesion far above industry requirements

✔ Reliable performance in cold weather, humidity, or complex substrates

✔ No cracking or poor adhesion during high-speed lamination or wrapping

This is a level many ordinary pvc decorative film products cannot achieve.

Why Does the Back Coating Become Even More Critical as the Weather Gets Colder?

Every winter, furniture factories start to worry about:

·Glue becoming slower to cure

·Higher moisture content in substrates

·Poor adhesion during lamination

·Curved surfaces lifting after wrapping

But experience shows:

The real key is not the temperature—it is whether the back coating is strong enough.

High-quality back coating maintains sufficient wetting ability even in low temperatures, ensuring quick bonding between the glue and the pvc decorative film, preventing delamination issues during winter.

This is why many factories prefer:

·HanTai wood grain self adhesive film

·HanTai marble pvc decorative film

·HanTai matte soft-touch pvc film

·HanTai super-adhesion back-coated pvc film

The better the back coating performance, the more stable the winter processing.

What Serious Issues Occur If There Is No Back Coating or If It Is Not Up to Standard?

Many companies experience major losses because they purchased low-cost films, such as:

·Severe delamination 2–3 months after wrapping

·Edges lifting after flat lamination

·Higher glue consumption but still poor adhesion

·Customer complaints, rework, and scrapping of finished goods

·Large areas of wood grain or stone grain surfaces failing

Worst of all, you may not know the real cause—

often it is not the machine, not the glue, but unqualified back coating.

Why Can HanTai Achieve Superior Back Coating Adhesion? What Technologies Do We Use?

As a national high-tech enterprise, Guangdong HanTai Decorative Materials Co., Ltd. focuses on R&D and manufacturing of pvc decorative film. Our back coating technology uses:

·Automated precision coating systems

·High-polymer modified back coating formulations

·Strict spectrophotometer and surface energy testing

·Online tension monitoring systems

·High–low temperature cyclic adhesion simulation experiments

HanTai’s advanced back coating is used across:

·wood grain self adhesive film

·marble pattern pvc decorative film

·high-gloss PET decorative film

·matte soft touch pvc film

·antibacterial engineering-grade decorative film

Whether you are a furniture factory, door factory, cabinet manufacturer, or building materials distributor, you can obtain highly compatible and stable pvc decorative film.

Conclusion: How Do You Ensure You Choose Truly Reliable PVC Decorative Film?

To avoid delamination, rework, customer complaints, and product failure, the only core solution is:

Choose pvc decorative film with high-quality back coating to guarantee long-term adhesion stability.

HanTai’s back coating performance far exceeds industry standards, achieving stable performance above 60 dyne, ensuring easier, more efficient, and more reliable processing.

If you are looking for:

·More stable wrapping results

·Stronger adhesion pvc decorative film

·High-quality wood grain self adhesive film or stone decorative film

·A professional and reliable manufacturing partner

You are always welcome to contact us.

📩 Guangdong HanTai Decorative Materials Co., Ltd.

— Specialist in PVC / PET decorative film R&D and production

— Provider of enhanced back-coated high-adhesion PVC decorative film

— Supports customized colors, embossing, and textures

— Exported to 60+ countries, trusted for stable quality