When it comes to selecting the right type of film for various applications, PET and PVC are two popular options. PET and PVC films each have distinct properties and benefits that make them suited for certain applications. We will explore the differences between PET film and PVC film and let you choose the suitable one that meets your needs in this article.

What Is The PET Film?

PET film is a versatile thermoplastic material that is widely used in various industries. It is known for its exceptional clarity, high tensile strength, and dimensional stability. PET film is made by extruding PET resin, which results in a thin, flexible sheet with outstanding mechanical qualities. Because of its transparency and glossy surface, it is an excellent choice for applications requiring aesthetic appeal, such as packaging and laminating.

What Is The PVC Film?

PVC film, on the other hand, is a durable and flexible plastic material that offers a wide range of applications. It is produced by polymerizing vinyl chloride monomers, resulting in a flexible sheet that can be easily manipulated. PVC film is recognized for its strong chemical resistance, making it ideal for applications involving severe chemicals.

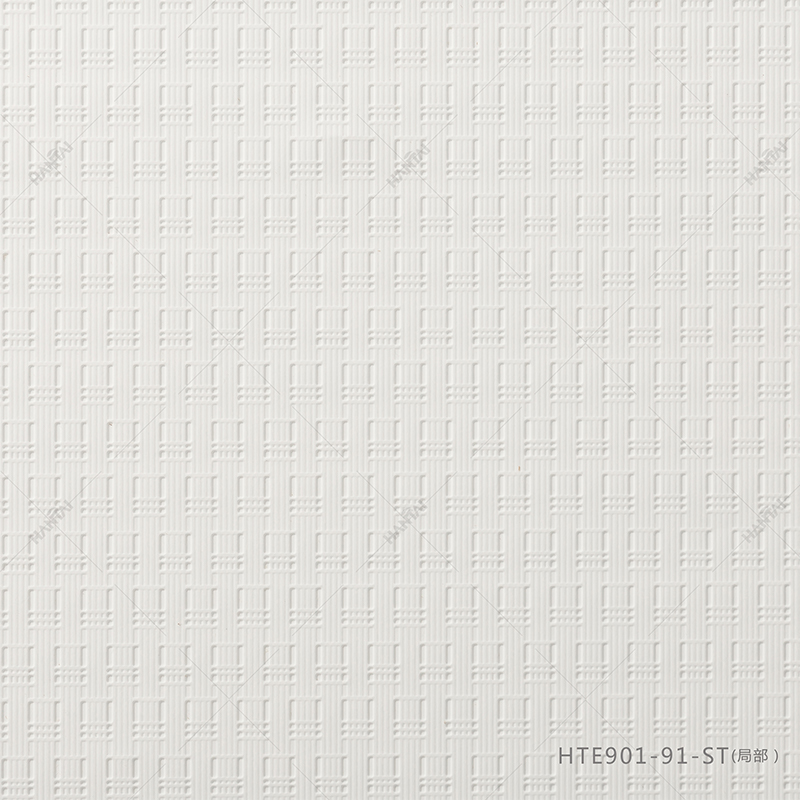

Solid Pvc Film For Living Room Furniture Lamination

What Are The Differences Between Them?

Here are the differences between them as the following:

Thickness And Gauge

PET film and PVC film are available in various thicknesses and gauges to cater to different application requirements. PET film is known for its uniform thickness, which ensures consistent performance across the film. It can be manufactured in thin gauges, ranging from microns to a few millimeters, making it suitable for applications that require lightweight and flexible films. PVC film is also available in a variety of thicknesses, giving greater flexibility in selecting the right gauge for certain applications. Depending on the necessary strength and durability, it is available in both thin and thick gauges.

Surface Finish

PET film typically features a smooth and glossy surface finish, contributing to its aesthetic appeal and enhancing visual clarity. The smooth surface allows for excellent printability, making it suitable for applications that require high-quality graphics or labeling. In contrast, depending on the production process and the precise formulation of the film, PVC film may have a somewhat rough or matte surface finish. Depending on the intended application, the textured surface may provide benefits such as greater grip, decreased glare, or increased slip resistance.

Barrier Properties

PET film has excellent barrier qualities, notably for moisture, gases, and smells. Because of its inherent barrier qualities, it is an excellent choice for applications requiring protection against moisture entry or gas infiltration. PET film helps maintain the freshness and quality of packaged products by acting as a barrier to external factors. PVC film also offers a certain level of barrier properties, although not as high as PET film. It provides some protection against moisture and gases, which can be advantageous in specific applications.

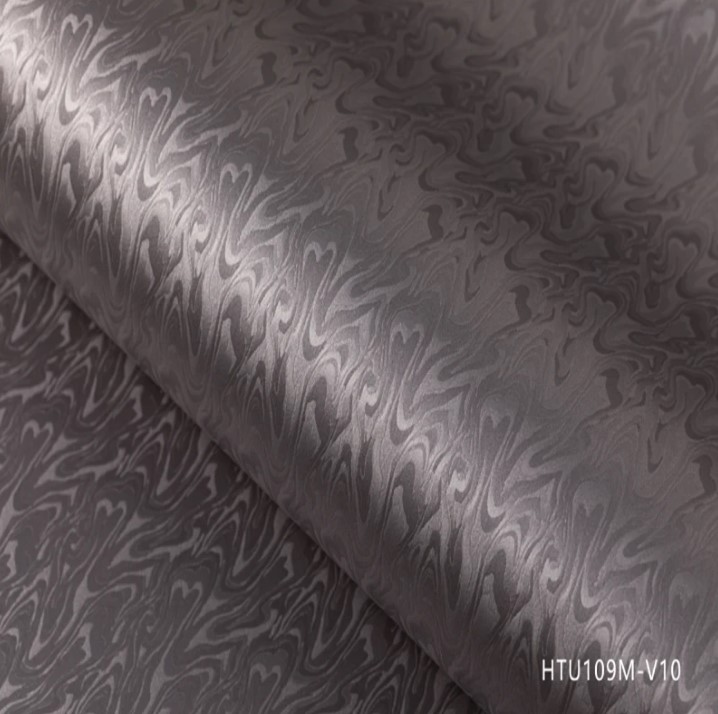

Pvc Wrapping Film Manufacturer

Optical Properties

PET film boasts excellent optical properties, including clarity, transparency, and light transmission. It offers outstanding visual clarity with minimal haze or cloudiness, ensuring a clear view of the contents. This makes it a preferred choice for applications where transparency and visibility are crucial, such as displays, windows, or packaging where the product needs to be showcased. While PVC film is somewhat less transparent than PET film, it still has acceptable optical characteristics. Depending on the exact application needs, it provides for appropriate light transmission while maintaining a balance between visibility and privacy.

Thermal Properties

PET film exhibits excellent thermal stability and can withstand a wide temperature range without significant deformation or degradation. It possesses a high melting point and demonstrates remarkable heat resistance, making it suitable for applications involving thermal processes such as heat sealing or lamination. PET film retains its structural integrity and functionality even when exposed to elevated temperatures. PVC film has strong thermal characteristics and can endure mild temperatures. PVC film, on the other hand, has a lower melting point than PET film and may necessitate special attention for high-temperature applications.

Conclusion

PET film and PVC film are two distinct materials with their own set of properties and applications. Besides, if you are looking for high-quality PET film and PVC film for furniture decoration, HANTAI is ideal for you. We are devoted to providing various furniture decoration films and vehicle wraps. Experience the difference with HANTAI products. Take action and order now!