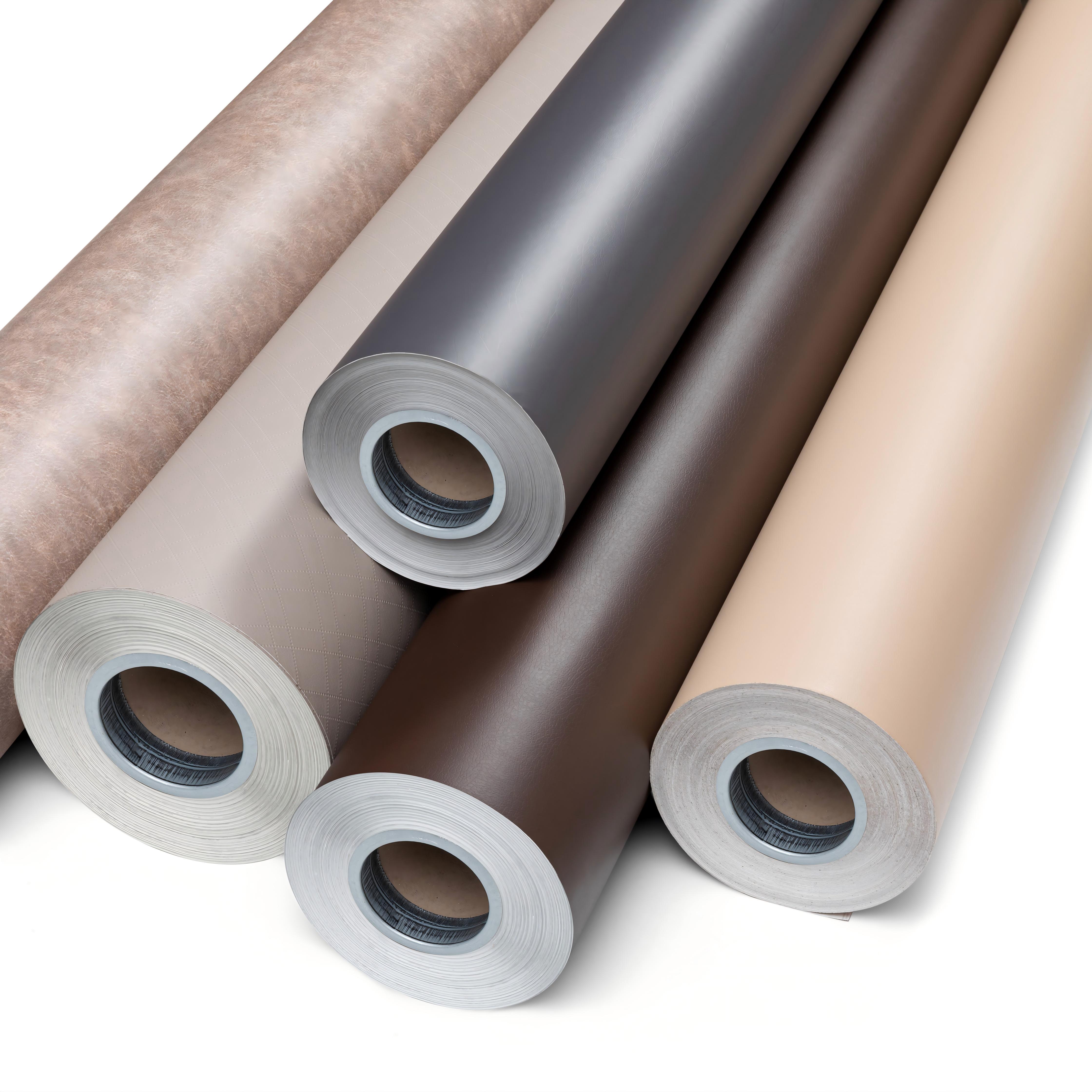

Does a Hot and Humid Climate Affect the Lifespan of PVC Decorative Film?

— The Moisture Impact You May Be Overlooking Is Often the Real Key

Hot and humid climates are commonly found in Southeast Asia, Central America, South America, and many coastal regions. The defining characteristics of these environments are high humidity, strong moisture penetration, and sustained high temperatures. Under such conditions, standard PVC card-grade films or low-end decorative films often exhibit the following issues:

·Adhesive absorption of moisture leading to reduced bonding strength, edge lifting, or blistering

·Surface dullness or haze caused by moisture intrusion

·Accelerated plasticizer migration, resulting in brittleness or deformation

·Separation between the printed layer and the PVC layer, creating color spots or pattern distortion

However, high-performance PVC Decorative Film—such as those produced by HANTAI—behaves very differently in hot and humid environments. This performance advantage is rooted in three core technical factors:

1. Highly Stable Formulation Systems Reduce Moisture Absorption

The stability of PVC Decorative Film is largely determined by its formulation structure. HANTAI optimizes resin ratios, incorporates anti-hydrolysis additives, and refines plasticizer systems to significantly reduce moisture sensitivity. Even in environments with humidity levels exceeding 90%, the film maintains structural stability.

2. Chemical Back Primer Significantly Enhances Adhesion

In hot and humid conditions, physical surface treatments (such as standard corona treatment) tend to degrade over time. HANTAI uses a chemical Back Primer that reacts chemically with adhesives, ensuring consistently strong bonding performance. Measured dyne values remain stable between 38–60 dyne, far exceeding industry averages.

3. Sealed Surface Structure Resists Moisture Penetration

For customers in humid regions, HANTAI reinforces the surface moisture-resistant coating, allowing PVC Decorative Film to effectively block water vapor penetration. As a result, gloss stability and pattern clarity are maintained even in high-humidity applications such as bathroom cabinets, kitchen cabinetry, and balcony wardrobes.

Therefore, in hot and humid climates, PVC Decorative Film is not only suitable—it delivers durability beyond expectations.

Will Dry or Desert Climates Cause PVC Decorative Film to Become Brittle?

Dry climates such as those found in the Middle East, Central Asia, and inland western regions are characterized by low humidity, arid air, and large day–night temperature fluctuations. Many materials tend to suffer from brittleness, shrinkage, or color instability under these conditions, leading some to question whether PVC Decorative Film can remain stable in dry environments.

In reality, whether PVC Decorative Film becomes brittle depends on two key structural factors:

1. Plasticizer Stability Determines Long-Term Flexibility

Low-cost films often use inexpensive plasticizers that are unsuitable for extremely dry environments, causing the film to harden and become brittle as moisture levels drop. HANTAI’s PVC Decorative Film uses high-weather-resistance plasticizers, ensuring that flexibility does not depend on ambient humidity and remains stable even in extremely dry conditions.

2. Base Film Density Determines Dimensional Stability

Low-density base films are prone to dimensional instability due to temperature fluctuations. HANTAI employs high-density calendered PVC film, significantly improving dimensional stability. Whether applied to door panels, furniture, wall panels, or skirting boards, the film remains resistant to shrinkage and edge lifting.

Additionally, for high-temperature and dry regions, HANTAI reinforces the following properties:

·UV resistance

·Light-aging resistance

·Prevention of surface pigment migration

·Long-term clarity of wood grain, stone, and leather textures

As a result, PVC Decorative Film performs reliably in dry climates and maintains long-term structural stability.

Will Cold Climates Cause PVC Decorative Film to Harden or Crack?

— True Stability Is Proven at Sub-Zero Temperatures

Cold regions—such as Northern Europe, Canada, Russia, and Northeast Asia—impose a different set of extreme requirements, particularly low-temperature flexibility. If the formulation is inadequate, PVC Decorative Film may experience:

·Hardening

·Brittle cracking

·Adhesive shrinkage

·Surface crazing

·Edge lifting or delamination

To address these challenges, HANTAI customizes the structure of its PVC Decorative Film for cold regions, enabling it to maintain flexibility and adhesion at temperatures ranging from –20°C

Key advantages come from three aspects:

1. Low-Temperature Flexibility Testing Prevents Cold-Induced Cracking

HANTAI’s films undergo rigorous freeze testing, maintaining bendability without cracking under low-temperature conditions.

2. Low-Temperature Back Primer Technology Ensures Adhesive Performance

Standard back primers lose reactivity at low temperatures. HANTAI’s specially developed low-temperature back primer maintains chemical bonding performance, ensuring adhesion strength does not decline in cold environments.

3. Cold-Resistant Surface Layers Maintain Pattern Stability

Wood grain, fabric, and stone textures remain flat and stable under low temperatures, without blistering, stretching, or distortion.

For door panels, wardrobes, and wall panels in cold regions, PVC Decorative Film is a more stable solution than veneer, PET, or paint finishes.

The Essence of Cross-Climate Stability:

Why PVC Decorative Film Can Achieve “Global Applicability”

Achieving stable performance across hot, dry, and cold climates is not simply a matter of making the film “thicker” or “harder.” The true foundation lies in five integrated systems:

·High-density PVC base film structure

Ensures dimensional stability and weather resistance at the core level.·Climate-specific formulation systems

Designed to resist humidity, temperature extremes, UV exposure, and oxidation.·Chemical Back Primer technology

Keeps adhesion performance at the leading edge of the industry.·Application-specific surface layer reinforcement

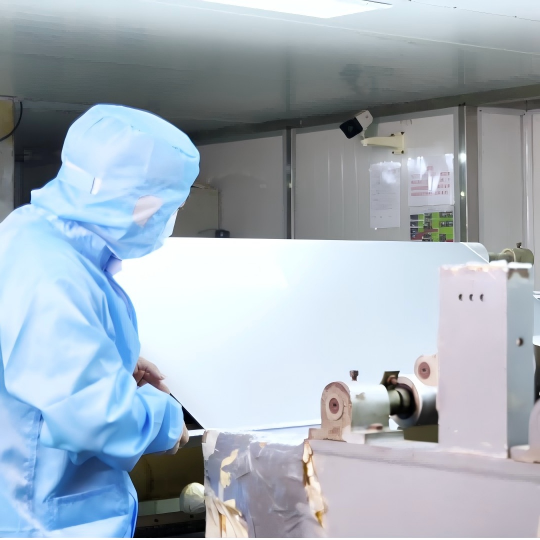

Including scratch resistance, stain resistance, moisture resistance, and thermal stability.·Full-process quality control

Covering formulation validation, dyne value testing, freeze testing, humidity resistance testing, and UV accelerated aging tests.

HANTAI PVC Decorative Film has been exported long-term to Northern Europe, the Middle East, Southeast Asia, Russia, North America, and South America, with proven performance across extreme climate zones.

Is PVC Decorative Film Suitable for All Climates?

From a technical perspective, PVC Decorative Film is fully capable of performing in hot-humid, dry, and cold climates—provided that its formulation, production process, back primer technology, and testing systems are professionally developed. As a specialized manufacturer, HANTAI has demonstrated the global reliability of its PVC Decorative Film through stable quality systems, extensive international project experience, high-standard dyne back coating, and rigorous climate testing.

Regardless of your climate zone, choosing HANTAI PVC Decorative Film means achieving:

·No edge lifting, no blistering

·No brittleness, no shrinkage

·No fading, no loss of gloss

·Long-term stable adhesion

·Highly realistic textures and surface depth

This is why we continue to maintain a strong professional reputation in global markets.

Choose PVC Decorative Film Designed for All Climates—and Take Your Products Global

If you are looking for:

✔ Cross-climate stable PVC Decorative Film

✔ High-adhesion back primer technology

✔ Strong adhesion performance of 38–60 dyne

✔ Suitability for hot-humid, dry, and cold extreme environments

✔ Globally recognized and consistently trusted quality

We invite you to explore HANTAI's PVC Decorative Film portfolio. We are always ready to provide technical documentation, in-depth consultation, and professional product selection support.