When it comes to packaging and industrial applications, choosing the right type of film is crucial. Among the numerous options available, polyethylene (PE) and polyvinyl chloride (PVC) films are two widely used materials. Understanding the distinctions between these two materials is critical for making well-informed judgments based on unique needs. In this article, we will delve into the characteristics, uses, and environmental aspects of polyethylene and PVC films.

Polyethylene Film

Polyethylene is a thermoplastic polymer widely known for its versatility, flexibility, and ease of processing. There are two main types of polyethylene films: low-density polyethylene (LDPE) and high-density polyethylene (HDPE). LDPE films are more flexible and have higher elongation properties, making them suitable for applications such as packaging and plastic bags. On the other hand, HDPE films are more rigid and have higher tensile strength, making them excellent for heavier-duty applications such as industrial liners and construction films.

Key Characteristics Of Polyethylene Film

Flexibility And Rigidity

Polyethylene films come in two main types: LDPE (low-density polyethylene) and HDPE (high-density polyethylene). LDPE films are more flexible, offering higher elongation properties, and making them suitable for packaging and plastic bags. On the other hand, HDPE films are stiffer and have higher tensile strength, making them excellent for heavy-duty applications such as industrial liners and construction films.

Chemical Resistance

Polyethylene films exhibit excellent chemical resistance, enhancing their suitability for packaging a wide range of products. This chemical resistance guarantees that the films retain their integrity and safeguard the contents from any injury during storage or transit.

Recyclability

Polyethylene is highly recyclable, making it a sustainable choice in the packaging industry. The recyclability of PE films helps to conserve the environment by lowering the overall effect on landfills and supporting a circular economy.

Water Resistance

PE films are inherently resistant to moisture, making them an excellent choice for applications where protection against humidity and moisture is crucial. This feature is essential for safeguarding the quality and integrity of packed goods.

PVC Film

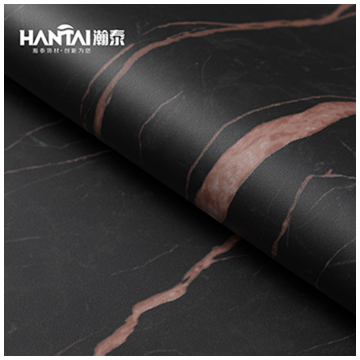

Polyvinyl chloride, commonly known as PVC, is another thermoplastic polymer used in the production of films. PVC films are known for their durability, clarity, and versatility. These films come in a variety of compositions, including plasticized and rigid versions, each with its own set of qualities for specialized purposes. Plasticized PVC films are flexible and often used in applications such as food packaging and cling films, while rigid PVC films find applications in construction, signage, and stationery products.

Key Characteristics of PVC Film

Durability

PVC films are renowned for their durability and high resistance to impact. This makes them suitable for applications where the film may be subject to physical stress or rough handling. PVC films' toughness adds to their endurance and dependability in a variety of sectors.

Clarity

PVC films have excellent optical clarity, making them an excellent choice where visibility is crucial. This clarity is advantageous in applications such as packaging, signage, and displays where the appearance of the product or message needs to be visible.

Versatility

PVC films are available in a variety of formulations, including plasticized and rigid kinds, allowing for customization based on application needs. This versatility ensures that PVC films can be tailored to meet the diverse needs of industries such as food packaging, construction, signage, and stationery.

Weather Resistance

PVC films have great weather resistance, making them appropriate for outdoor applications. This weather resistance ensures that the films maintain their structural integrity and performance characteristics even when exposed to varying environmental conditions.

Differences Between Polyethylene And PVC Films

Flexibility And Rigidity

The flexibility of polyethylene, especially LDPE, contrasts with the variable flexibility of PVC, which can be either flexible (plasticized PVC) or rigid. The decision between the two is dictated by the application's unique requirements.

Chemical Composition

Polyethylene is made up of carbon and hydrogen atoms, whereas PVC includes chlorine as well as carbon and hydrogen. This distinction in chemical composition contributes to differences in properties such as flexibility, transparency, and weather resistance.

Transparency

PVC films often have higher optical clarity than polyethylene films. The higher transparency of PVC makes it a preferred choice in applications where visual aesthetics or product visibility are essential.

Environmental Considerations

Polyethylene is more readily recyclable than PVC, making it a more environmentally friendly option. Polyethylene's recyclability coincides with sustainable practices and lowers the environmental effect of plastic trash.

Conclusion

In summary, the choice between polyethylene and PVC films depends on specific application requirements. While both materials have advantages, knowing the variations in flexibility, chemical composition, transparency, and environmental effects can help guide the decision-making process. As a leading PVC film supplier, HANTAI specializes in providing top-quality car wraps and Interior Decoration. Please feel free to contact us today!

FAQs

1: Is PVC more environmentally friendly than polyethylene?

Answer:

While both materials have their environmental considerations, polyethylene is generally considered more environmentally friendly than PVC. Polyethylene is highly recyclable, contributing to sustainability efforts and reducing the overall environmental impact. PVC, on the other hand, involves more complex recycling processes and may release chlorine gas during incineration, posing potential environmental challenges.

2: Can polyethylene and PVC films be used interchangeably?

Answer:

The choice between polyethylene and PVC films depends on specific application requirements. Polyethylene films, especially LDPE and HDPE, are known for their flexibility and adaptability, making them suitable for various packaging needs. PVC films, with their durability and optical clarity, are often chosen for applications where visibility and impact resistance are crucial. While there may be some overlap in applications, each material has unique properties that cater to specific demands.

3: How do these films contribute to sustainability?

Answer:

Polyethylene films contribute to sustainability through their high recyclability. The ease of recycling polyethylene helps reduce the environmental impact of plastic waste. PVC films, while versatile, face challenges in recycling due to their chemical composition. However, advancements in recycling technologies are making strides to address PVC's environmental impact. Choosing either material with a focus on recycling and responsible disposal practices contributes to more sustainable packaging solutions.