PVC film, also known as polyvinyl chloride film, is an essential material in a myriad of industries due to its durability, flexibility, and resistance to environmental factors. The manufacturing process of PVC film is intricate and involves several critical steps that transform basic raw materials into the versatile film used in countless products. In this article, we delve into the detailed production process of PVC film, highlighting each stage from sourcing raw materials to final distribution, to help you understand why PVC film is so widely utilized and how its quality is maintained through rigorous manufacturing standards.

Step 1: Sourcing Raw Materials

To kickstart the PVC film manufacturing process, it is crucial to source high-quality raw materials. The main ingredient, PVC resin, is a product of the chemical reaction between ethylene, derived from petroleum or natural gas, and chlorine, obtained from industrial-grade salt. The availability and quality of these raw materials are paramount, as they lay the foundation for the film's performance characteristics. Suppliers are carefully selected to ensure a reliable and consistent supply chain, which is vital for maintaining the production flow and quality of the PVC film.

Step 2: Polymerization

The polymerization process begins after the raw components are gathered. In a regulated atmosphere, ethylene and chlorine are combined to make vinyl chloride monomers. This process typically utilizes a catalyst, such as a free-radical initiator, to initiate the chemical reaction.

Step 3: Vinyl Chloride Monomer Conversion

The vinyl chloride monomers are then polymerized in the next step. The monomers are linked together to create lengthy chains, resulting in a polyvinyl chloride resin. This resin has a white, powdery look and serves as the foundation for PVC film.

Step 4: Plasticization

To make the rigid PVC resin flexible, plasticizers are added. Plasticizers are organic compounds that act as softening agents by increasing the resin's mobility and reducing its glass transition temperature. The most commonly used plasticizer for PVC film is called di-2-ethylhexyl phthalate (DEHP). The plasticization process involves blending the PVC resin with the desired amount of plasticizer, typically in a heated mixer.

Step 5: Film Extrusion

The PVC film is ready to be manufactured after the plasticization process is completed. The PVC resin and plasticizer blend is fed into an extruder, a machine with a revolving screw, during the film extrusion process. The material is heated and melted within the extruder before being pressed through a die that provides the film with the correct thickness and breadth. To solidify the extruded film, it is immediately chilled.

Step 6: Surface Treatment

To enhance the film's surface properties and improve printability, surface treatment may be applied. This entails treating the film to corona discharge or flame treatment, which enhances its surface energy and enables better adherence to inks, coatings, or adhesives.

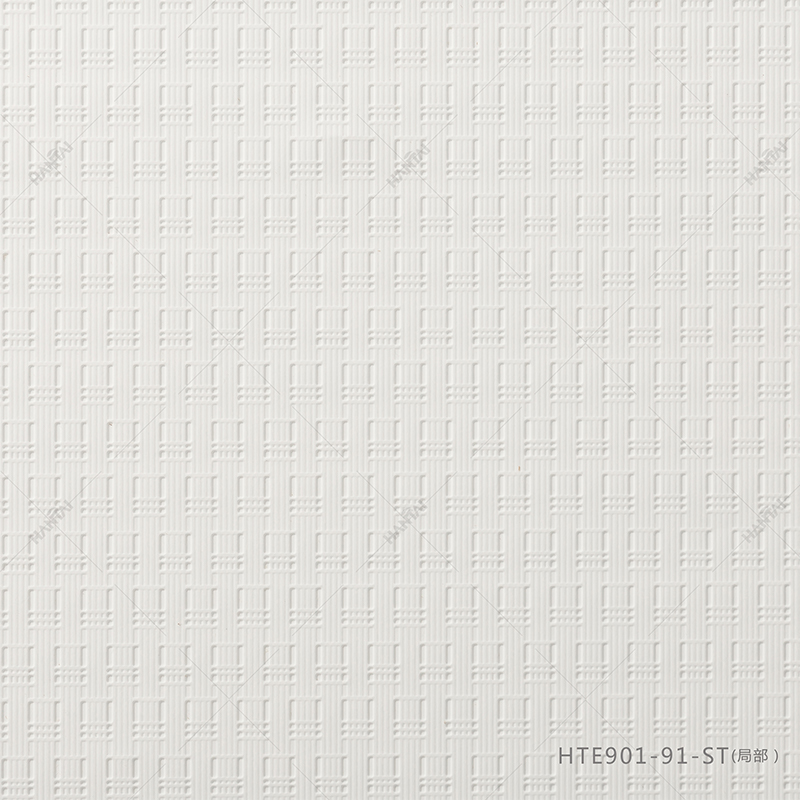

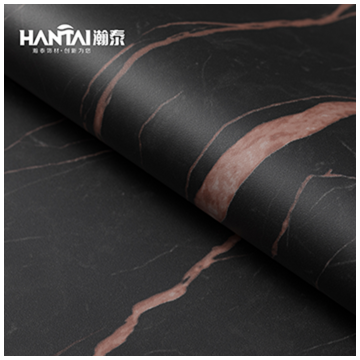

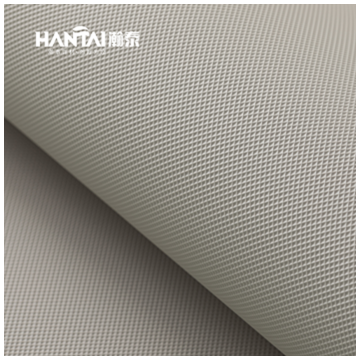

Step 7: Additional Processing and Finishing

Additional processing and finishing stages may be required depending on the desired properties of the PVC film. These can involve embossing or laminating the film with additional materials to improve its look, durability, or utility, such as polyester or metal foils.

PVC Film For Display Cabinet Lamination

Step 8: Quality Control and Testing

Throughout the production process, rigorous quality control measures are implemented to ensure the PVC film meets the required specifications. This includes testing mechanical parameters like tensile strength and elongation, as well as assessing other aspects such as transparency, color uniformity, and dimensional stability.

Step 9: Packaging and Distribution

Once the PVC film passes quality control, it is packaged and prepared for distribution. The film is typically wound onto large rolls or cut into sheets, depending on customer requirements. It is then delivered to other businesses for use in packaging, industrial curtains, vinyl flooring, window films, and other uses.

Conclusion

In conclusion, the PVC film manufacturing process is a complex yet meticulously controlled sequence of events that ensures the transformation of simple raw materials into a multifunctional product that meets the demands of various industries. Each step, from the precise polymerization to the final quality assurance, is designed to produce PVC film that adheres to the highest standards of quality and performance. For those in search of premium PVC film solutions, HANTAI offers a range of products tailored to your specifications. To explore our extensive selection and find the PVC film that fits your needs, contact us today for more information and expert guidance.