Polyethylene terephthalate, commonly abbreviated as PET, is a type of polyester that is molded into a variety of products, including films known for their strength and versatility. The full form of PET film reveals its chemical structure: a polymer resin of the polyester family that is extruded into a film. This material is renowned for its remarkable balance of properties that are beneficial across multiple industries, from packaging to automotive applications.

In this article, we delve into the top 10 physical properties of PET film, providing a comprehensive overview that caters to the pressing queries of users seeking in-depth knowledge about this material. By understanding these properties, users can make informed decisions about the suitability of PET film for their specific needs.

Physical Properties of PET Film

The physical properties of PET material are critical to its performance in various applications. Below, we detail the top physical properties of PET film, offering insights into why this material is preferred for certain uses:

High Tensile Strength

PET film has a high tensile strength, which means it can withstand a considerable amount of stress without breaking or deforming. This makes it an ideal material for applications that require strength and durability.

High Heat Resistance

PET film has a high heat resistance, which means it can withstand high temperatures without degrading or melting. PET film can withstand temperatures of up to 150°C, making it suitable for applications that require high-temperature resistance.

Excellent Dimensional Stability

PET film has excellent dimensional stability, which means it does not shrink or expand significantly under different environmental conditions. This makes it an ideal material for applications that require precise dimensions and stability.

Exceptional Chemical Resistance

PET film has excellent chemical resistance, which means it can withstand the adverse effects of a wide range of substances. This makes it excellent for applications requiring chemical resistance, such as acids, bases, and solvents.

Clarity

PET film has excellent clarity, which makes it an ideal material for applications that require transparency. PET film can be made transparent or opaque depending on the additives used during the manufacturing process.

Low Moisture Absorption

PET film has a low moisture absorption rate, which implies it does not absorb moisture from its surroundings. This makes it an ideal material for applications that require low water vapor transmission rates.

Good Electrical Properties

PET film has excellent electrical characteristics, making it an appropriate material for a variety of electronic applications. PET film has a low dielectric constant and low dissipation factor, making it suitable for high-frequency applications.

UV Resistance

PET film has excellent UV resistance, which means it can resist the harmful effects of UV radiation. This makes it an ideal material for applications that require UV resistance such as outdoor signage, automotive films, and protective coatings.

Low Coefficient of Friction

PET film has a low coefficient of friction, which means it can slide easily over other surfaces. This makes it an ideal material for applications that require low friction such as conveyor belts and release liners.

High Gas Barrier

PET film offers excellent gas barrier qualities, preventing the passage of gases such as oxygen, carbon dioxide, and nitrogen. This makes it an excellent choice for applications requiring gas barrier qualities, such as food and medical packaging.

PET Film Applications and Availability

The diverse properties of PET film not only make it suitable for a myriad of uses but also highlight its adaptability to various environmental and mechanical stresses. These characteristics are why PET film is the material of choice for industries such as electronics, packaging, and automotive.

Conclusion

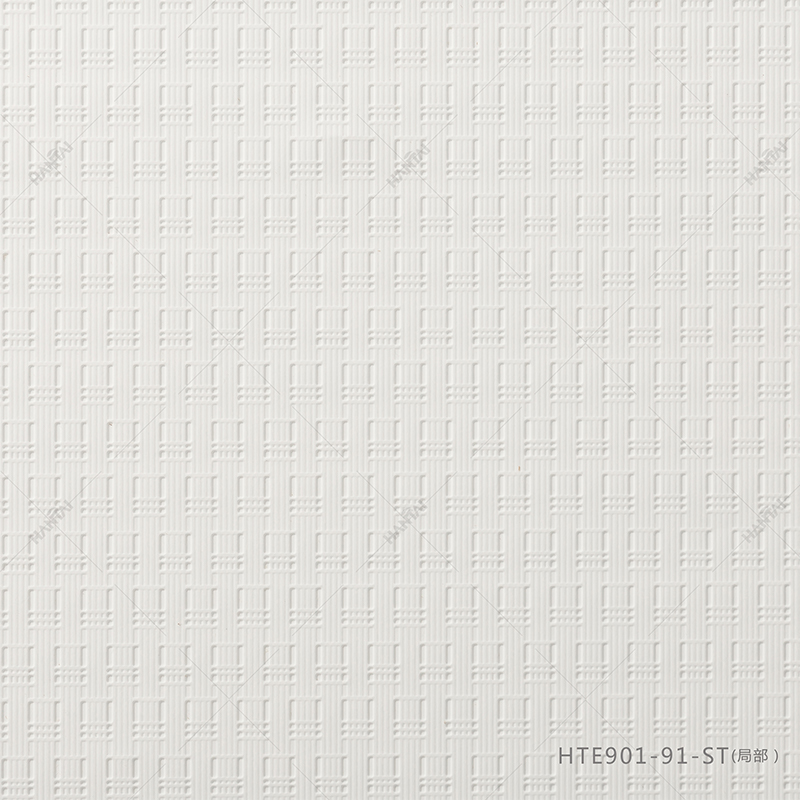

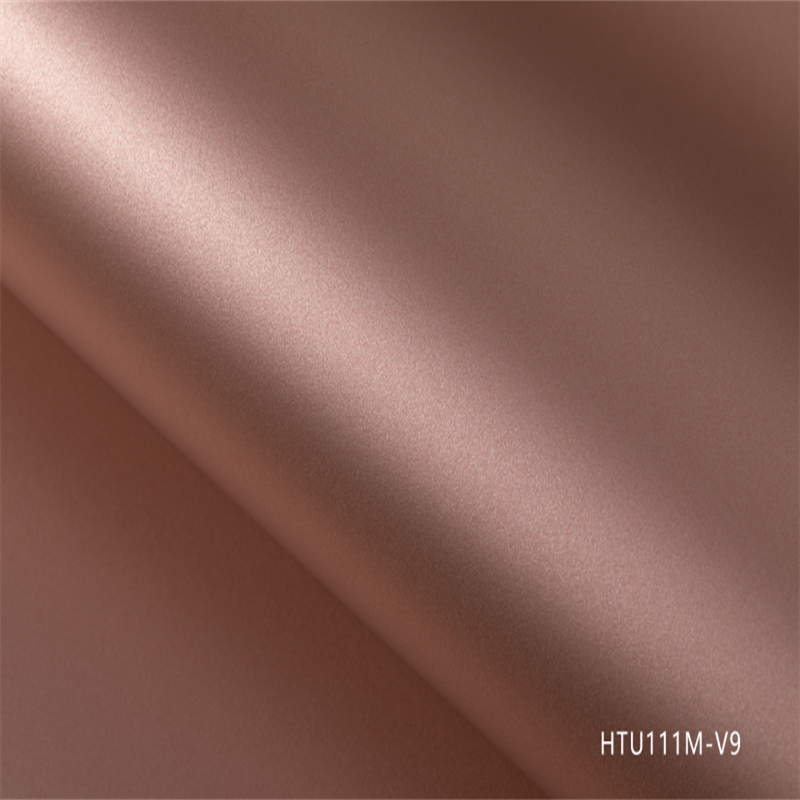

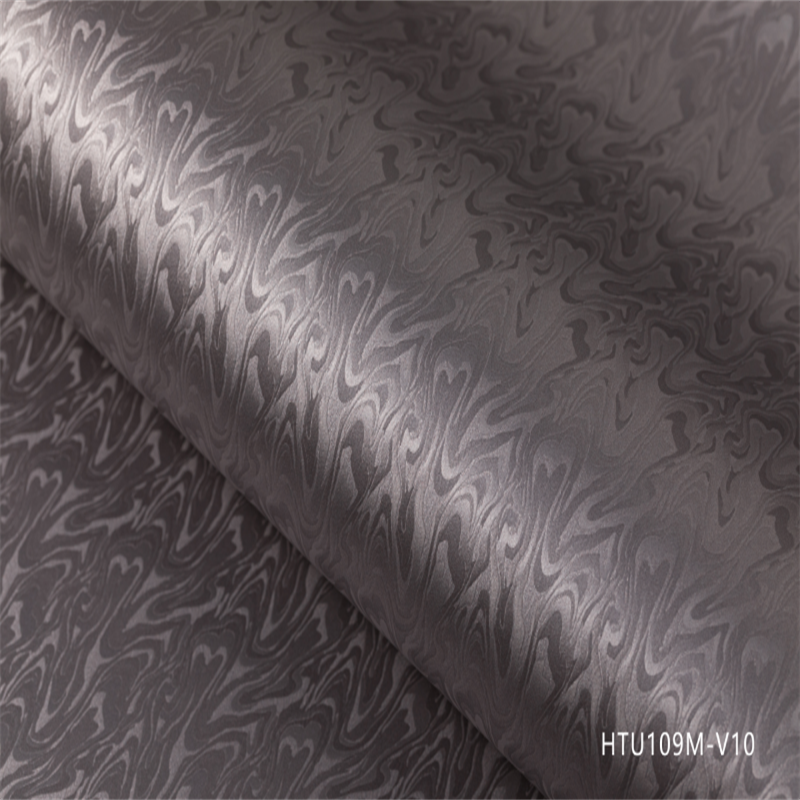

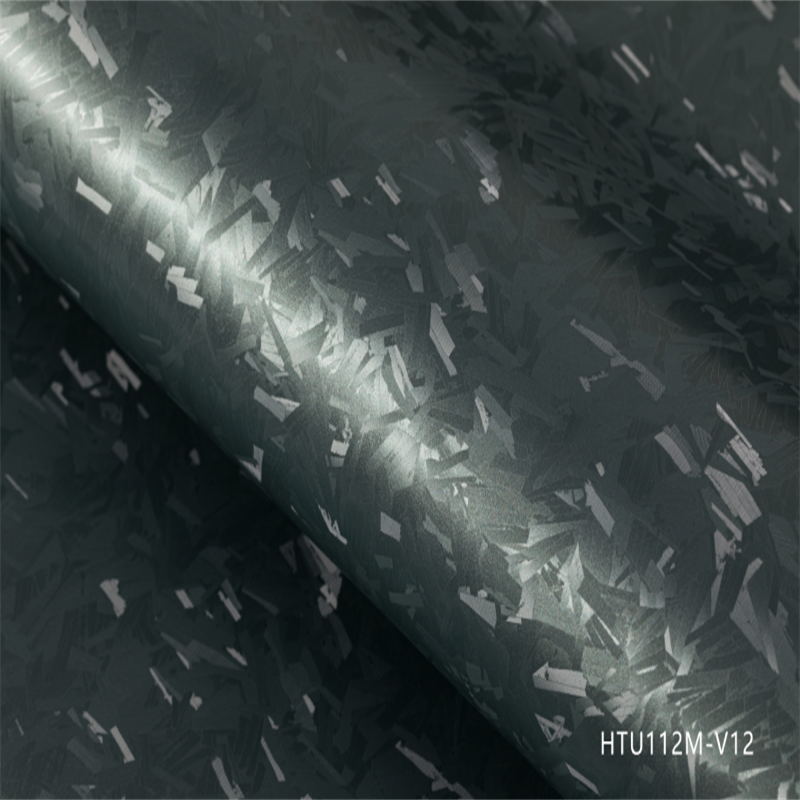

For those interested in acquiring PET film for their projects, our company, HANTAI, provides a vast selection of PET film types. Our inventory includes options like metalized PET film, which is perfect for reflective applications, as well as decorative films with marble and woodgrain patterns that enhance the aesthetic of furniture surfaces. To learn more about our full range of PET film products and to find the perfect solution for your application, please reach out to us. We are ready to assist you with detailed product information and expert guidance.